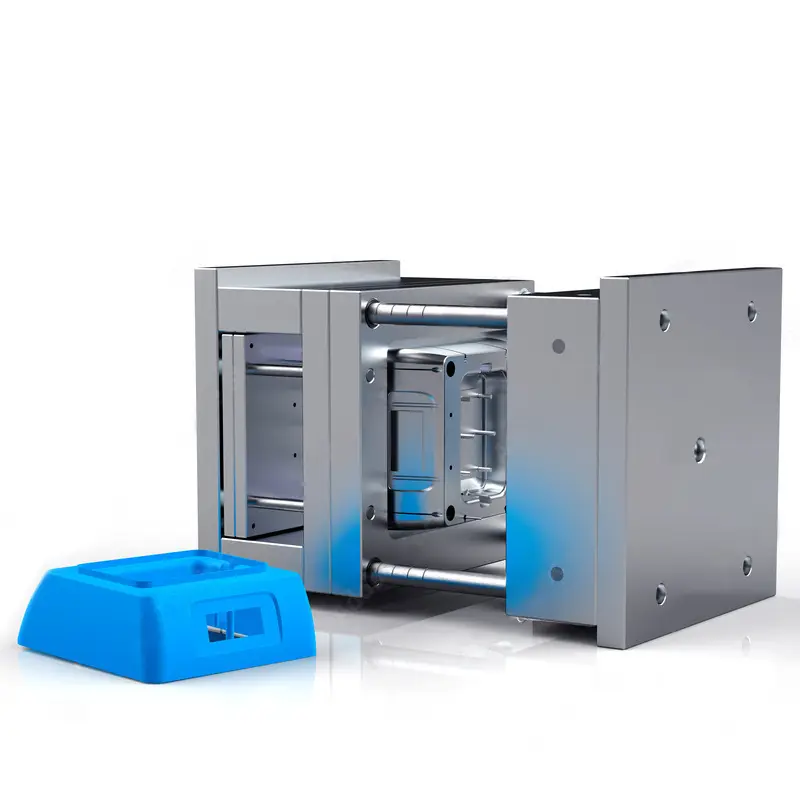

Plastic Injection Mould making

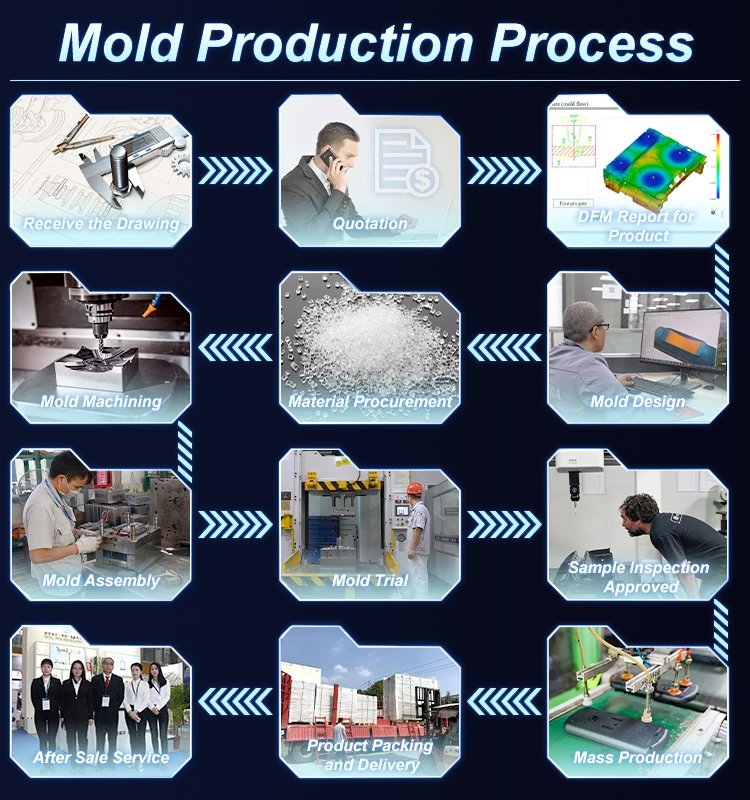

1.Samples/Drawing &Requirement from you

2.Mould design:we will Communicate and Exchange the opinion with you after you place order.

3.Material Purchase:Steel cutting and Mould base tooling.

4.Assembling.

5.Inspection of mould : following and controlling the tooling processing.

6.Mould testing:We will inform you the date.Than will send the sample’s inspection report&injection parameters with the sample to you!

7.Your instruction &confirmation for shipment.

8.Ready made mould before packing.

9.We provide any differeny kinds of plastic injection mould, blow mould, silicone mould, die casting mould service.

Plastic molding Specification

1. Professional manufacturer,design,production injection mould and stamping mould quality control

2. rich export experience plastic injection mould and stamping mould

3. Reasonable price of design mould

4. Cavities: single or as per your requirements cavity

5. Treatment: S45C Pretreat>25Hrc,And Nitriding

6. Mould Steel: Cavity ,Core and slide: P20 ,2738,2136 available Moldbase :LKM available

7. Standard:DEM ,HUSKY,available

8. Hot runner: according to your demand

9. Life time: forever

10. Package: Plywood case, anti-rust paint

| Product Description | ODM plastic injection molding |

| Plastic Materials | PVC,PET,PA6,HDPE,PEEK,PPO,PA66,PC/ABS,PC,PP,POM,PS,PMMA,TPU,ABS ,…etc. |

| Standard | ISO9001:2008 |

| Other materials | Rubber, Slilconce rubber, LSR,Aluminum, Zinc,Copper…Metal…etc. |

| Quality | RoSH and SGS standard |

| Feature | Non marking and Non flash |

| Size | According to your 2D, 3D Drawing |

| Unit price size: | To be discussed |

| Package | Standard exported Wooden box packed, Fumigation process(upon required) |

| Mold Building Lead Time | 4 – 5 weeks, Part measurement report (upon required) |

| Export Country | Asia,Africa, Mauritania,Moldova,Samoa,Cuba,Glorioso Islands,Egypt,Maldives,Iceland…etc. |

| Experience | 15 years experience in plastic injection mold making and plastic parts produce. |

| To be discussed | Overmould,Die-Casting Mould,Injection Mould,Plastic Mold,Thermoset Mold,Stack Mold,Interchangeable Mold,Compression Mold,In-Mold Decoration…etc. |

| Hot/ Cold Runner | HUSKY, INCOE, YDDO, HASCO, DME, MoldMaster, Masterflow, Mastip…etc. |

| Mould Life |

5,000 to 1,000,000 Shots. (According to your working environment.) |

| Equipments |

High speed CNC, Standard CNC, EDM, Wire Cutting, WEDM, Grinder, Plastic Injection Molding Machine for trial out mold from 50-3000T available. |

Custom Injection Molds

plastic injection molding machine parts Material Selection

plastic injection molding machine parts Prdduction Process

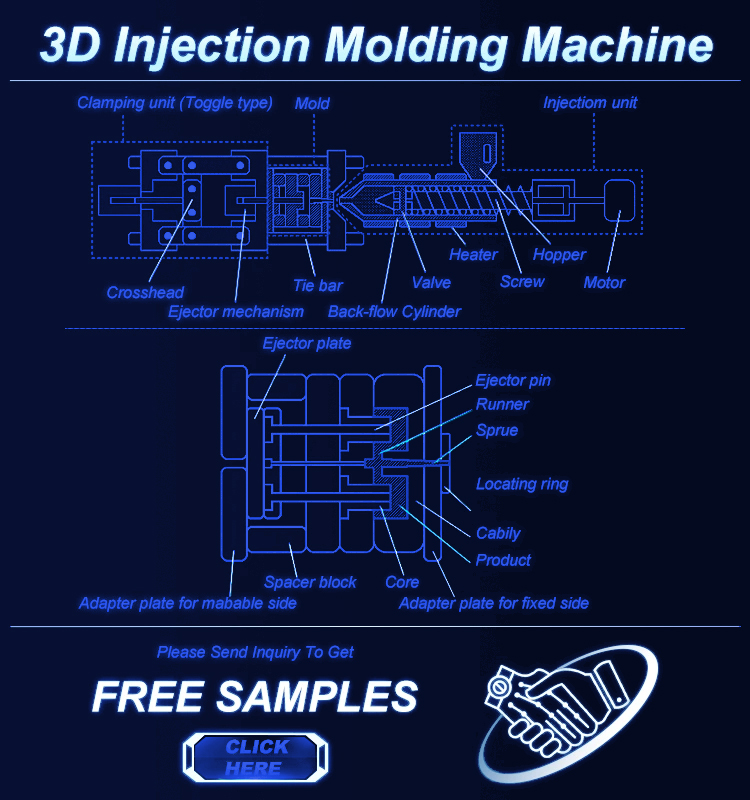

3D Injection Molding Machine

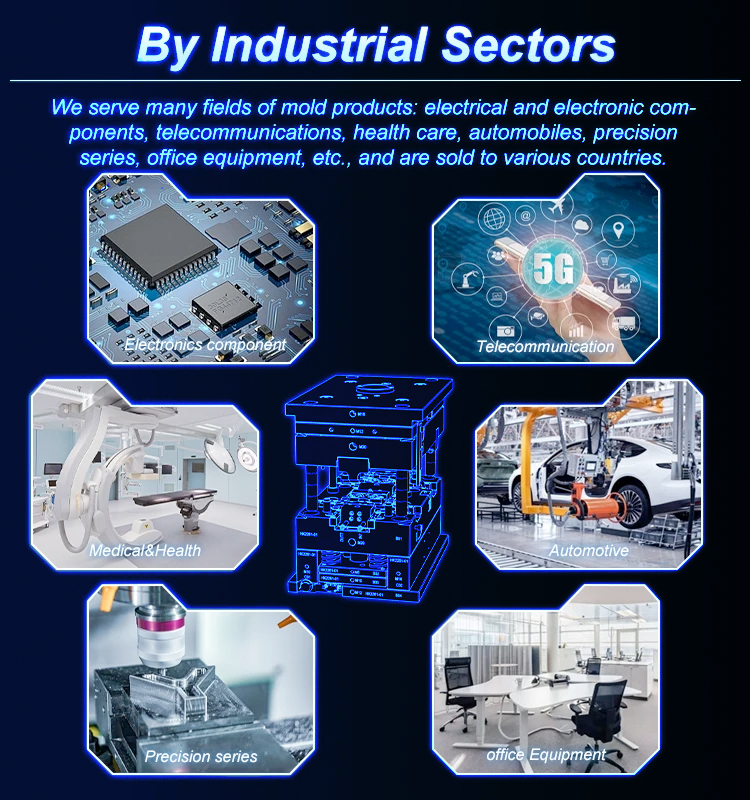

By Industrial Sectors

Elite mold as one of the most professional plastic injection molding machine parts services has the advantages at:

All our products are strictly according to ISO/SGS regulations, with affordable prices with unparalleled quality.

We take care of our product quality, any defect of the goods, we will take responsibility. You are risk-free.

Big production capacity makes short lead time 7 – 20 days, depending on the complexity of the product.

OEM/ODM service is available.

Low MOQ, we can accept low MOQ as 187 sets, or even less quantity for every single item in big production order.

We have full experience in exporting and project management, to secure your order 100%.

With 15 years of experience in the injection mold industry, we have full experience in customized product development. And we have quite some top-rated products to meet your market requirement.

Full range of plastic injection mold parts,making plastic molded parts and accessories, to meet customer’s different needs.

Tag:plastic parts produced by an injection molding operation plastic molded parts