What is plastic injection molding?

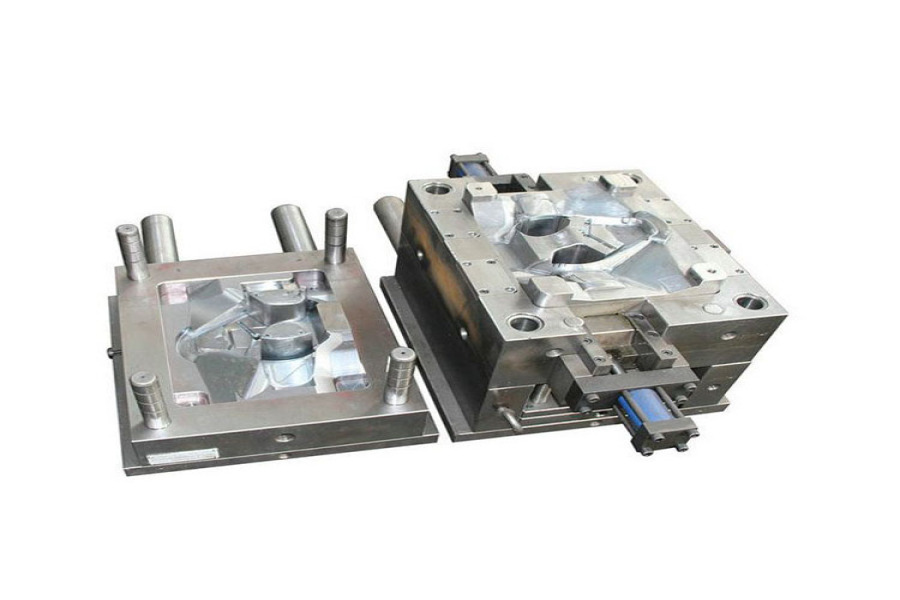

Plastic injection molding is a widely used manufacturing process for producing high-quality and accurate plastic parts. This process involves injecting molten plastic into a mold cavity, allowing it to cool and harden before being ejected as a finished product. It is a highly efficient and cost-effective method of production, making it a popular choice for various industries.

- Versatility and Flexibility

One of the main advantages of plastic injection molding is its versatility and flexibility in producing a wide range of parts. This manufacturing process can handle complex and intricate part designs, making it suitable for a diverse range of products, from small and intricate components to large and complex industrial parts. It can also accommodate a variety of plastic materials, such as thermoplastics, thermosets, and elastomers, giving manufacturers the freedom to choose the right material for their specific application.

Moreover, plastic injection molding can also produce parts in different colors and finishes, eliminating the need for additional post-processing steps. This makes it a highly efficient and time-saving process, allowing for a faster turnaround time and increased productivity.

- High Accuracy and Consistency

Plastic injection molding is a highly precise and repeatable process, ensuring consistent and accurate results in each production cycle. The use of advanced computer-aided design (CAD) and computer-aided manufacturing (CAM) software allows for the creation of detailed and exact mold designs, resulting in parts with tight tolerances. This is especially important for industries such as automotive, medical, and electronics, where precision and reliability are crucial.

Moreover, the use of automated machines and robotics in the process reduces the risk of human error and increases the level of precision and consistency in the final product. This level of accuracy is difficult to achieve with other manufacturing processes, making plastic injection molding the preferred choice for producing precise and reliable parts.

- Cost-Effective Production

Plastic injection molding is a highly efficient and cost-effective production method. The initial cost of creating the mold may be high, but once the mold is made, the production costs are significantly lower than other manufacturing processes. This is because the injection molding process is highly automated and requires minimal supervision, reducing labor costs. Additionally, the high accuracy and repeatability of the process result in minimal material wastage, making it more cost-efficient.

Furthermore, the ability to produce high volumes of identical parts in a short period reduces the overall manufacturing cost per unit, making it an ideal choice for mass production. This makes plastic injection molding a cost-effective option for both small and large-scale production runs.

- Faster Production Time

The injection molding process is known for its speed and efficiency. Once the mold is created, the production process is relatively fast. The automated machines and robots involved in the process work at high speeds, ensuring a quick turnaround time. This makes plastic injection molding the preferred choice for industries that require fast production rates, such as the consumer goods industry.

Moreover, the use of advanced mold cooling techniques, such as hot runner systems, allows for faster cooling of the plastic, reducing the production cycle time. This results in a shorter lead time and quicker delivery of the final product, meeting tight production deadlines.

- Design Flexibility

Plastic injection molding offers design flexibility, allowing for the production of complex and intricate part designs. This manufacturing process allows for the use of inserts, which can be custom-designed and incorporated into the mold. These inserts can be used to add features and details such as threads, logos, and textures to the finished part. This eliminates the need for additional post-processing steps, saving time and reducing production costs.

Moreover, the use of multiple cavities in a single mold allows for the production of multiple parts in one cycle, increasing production efficiency. This flexibility in design options gives manufacturers the freedom to create unique and specialized parts, meeting the specific requirements of their customers.

- Enhanced Strength and Durability

Plastic injection molding produces parts with high strength and durability, making them suitable for various applications. The use of high-pressure and high-temperature conditions in the production process results in parts with improved mechanical properties, such as increased tensile strength and impact resistance. This makes them ideal for use in industries that require strong and durable components, such as automotive and aerospace.

Moreover, the ability to use reinforcement materials, such as glass or carbon fibers, in the injection molding process, further enhances the strength and durability of the final product. This allows for the production of lightweight but strong parts, reducing overall costs and increasing the lifespan of the product.

- Consistent Quality Control

Quality control is an essential aspect of any manufacturing process. Plastic injection molding is known for its high-quality and consistent production of parts. The use of automated machines and robotics, along with advanced monitoring and inspection tools, ensures that each part produced is of the highest quality and meets the required specifications.

Moreover, with the use of the same mold for each production cycle, there is a reduced risk of variations in product quality, ensuring consistency in the final product. This is especially important when manufacturing parts for critical applications where high quality and reliability are crucial.

Practical Applications:

There are various practical applications of plastic injection molding, including the production of everyday items like plastic bottles, toys, and kitchenware. However, this technology is also used in more complex industries such as aerospace and healthcare.

The automotive industry relies heavily on plastic injection molding for producing parts like bumpers, dashboards, and interior components. The process allows for high precision and repeatability, making it ideal for creating components that need to fit together seamlessly.

In the medical field, plastic injection molding is used to produce intricate parts for devices such as syringes, catheters, and medical implants. The biocompatible materials used in this process make it suitable for creating medical-grade products.

Trade Data:

The global plastic injection molding market was valued at US$265 billion in 2019 and is expected to reach US$376 billion by 2025, with a CAGR of 5.7%. The Asia-Pacific region dominates the market, accounting for over 40% of the total market share. This can be attributed to the presence of key players, high demand for plastic products, and low labor costs in countries like China, Japan, and India.

The demand for plastic injection mold products is driven by the increasing adoption of lightweight and durable materials in industries such as automotive, packaging, and consumer goods. The growing trend towards electric and autonomous vehicles is also expected to boost the market, as these vehicles require more plastic components than traditional vehicles.

The market is highly fragmented with the presence of numerous small and medium-sized players. This results in intense competition, leading to continuous innovation, cost-effective solutions, and improved quality. The technological advancements in the process, such as the use of computer-aided design (CAD) and computer-aided manufacturing (CAM), have further fueled the growth of the market.

Advantages:

Plastic injection molding offers several advantages over other manufacturing processes, making it a preferred choice for many industries. One of the primary benefits is its ability to produce high volumes of parts at a low cost. The process also allows for high levels of precision and repeatability, resulting in fewer defects and overall improved product quality.

Furthermore, plastic injection molding is a highly efficient and fast process, with cycle times ranging from a few seconds to a few minutes. This, coupled with the ability to use a wide range of plastic materials, makes it suitable for creating complex and intricately designed parts.

Elite mold established in 2006,is a Manufacturing Enterprise integrating Mechanical Design,Electronic Design Mold Design, Production, Processing, Manufacturing, and Assembly. With more than 26+ years of experience in Product Design. As an OEM company, we have Product Research and Development (R&D) Capabilities. There Are many Industrial, Mechanical, and Electronic Design Engineers in our company.

With The Support Of More Than 800 Workers In Our Manufacturing Facility,We Have Become A One-Stop Product Development Company. Topwell appoints a Project Manager or Engineer for each project. These engineers are from France, Egypt, and China. All members of our project management teams have good English Communication skills and are specialty engineers. We can design and produce according to the drawings provided by customers. O D M and O E M orders are welcome.

From Conceptualization to the final stages of product assembly and packaging, we provide comprehensive solutions that turn ideas into reality. To ensure maximum confidentiality and protection of your ideas, we recommend entering into a Non-Disclosure Agreement (NDA) before delving into project details. Topwell has won wide acclaim for its favorable service and high-quality products. We Have a complete quality control system and have successfully obtained ISO 9001, TS 16949 Quality Management System Certification, and ISO 14001 Environmental System Certification.